Applet

Scan code for more attention

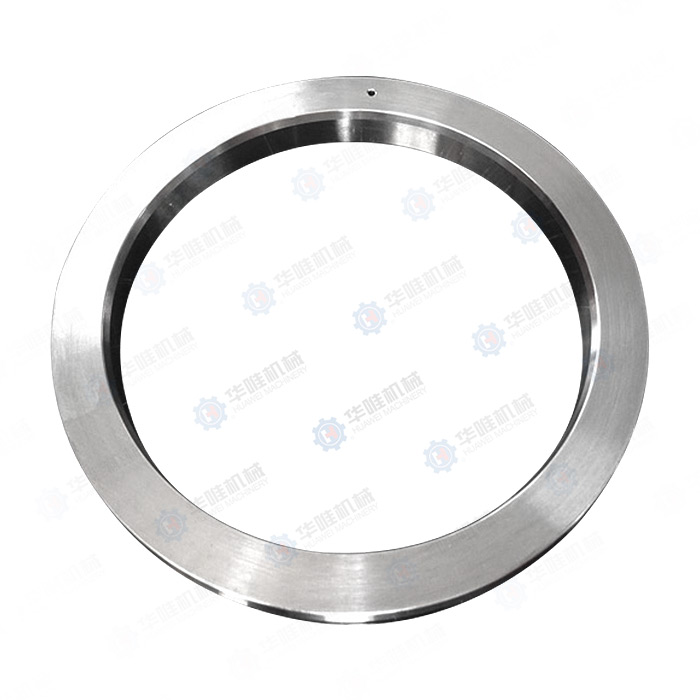

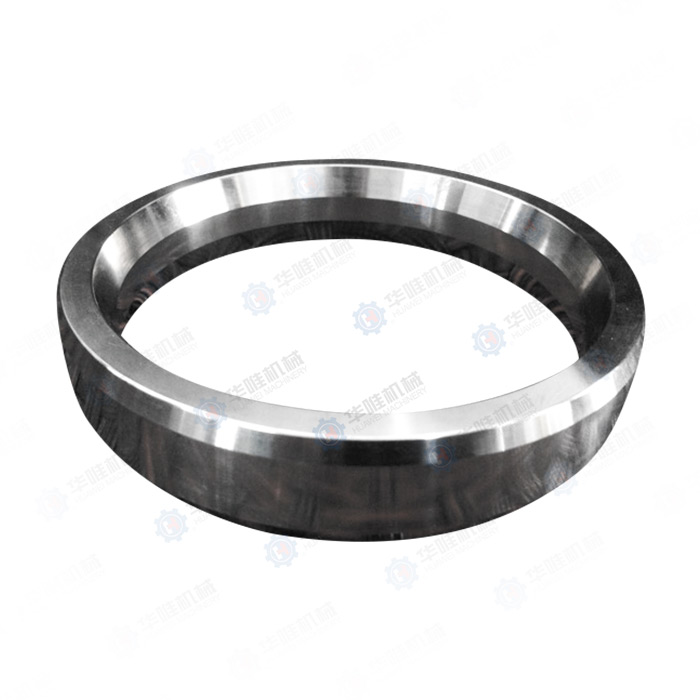

Valve sealing is the most important component of the entire valve type, whose main purpose is to prevent leakage. The valve sealing seat, also known as the sealing ring, is an organization that directly contacts the medium in the pipeline and prevents the medium from flowing. During the use of valves, there are various media in the pipeline, such as liquids, gases, oils, corrosive media, etc. Different valve seals are used in different places and can adapt to different media.

catalogue

Common sealing materials

Soft sealing materials and their applications

Hard sealing materials and their applications

1. Common sealing materials

Nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), fluororubber (VITON), fluoroplastic (PTFE), copper alloy, hard alloy

2. Soft sealing materials and their applications

Butterfly valves, ball valves, and solenoid valves typically use soft seals, but if the temperature and pressure are particularly high, hard seals will be selected accordingly.

(1) Nitrile rubber (NBR). Nitrile rubber has excellent oil resistance; Better heat resistance than natural rubber and styrene butadiene rubber; Good air tightness and water resistance. Dingjing rubber can be divided into Dingjing-18, Dingjing-26, and Dingjing-40. Xiangjing rubber is suitable for petroleum products, benzene, toluene, water, acid, and alkali media with temperatures ranging from -60 to+120 degrees Celsius.

(2) Fluororubber (VITON). Fluororubber is heat-resistant, acid and alkali resistant, oil resistant, and resistant to saturated water and steam. It has small compression permanent deformation and good air tightness. Fluororubber is suitable for petroleum products, water, acids, and alcohols with temperatures ranging from -30 to+220 degrees Celsius.

(3) Polytetrafluoroethylene (PTFE). Polytetrafluoroethylene is resistant to high temperatures and chemical corrosion, but it is not suitable for melting alkaline metals, fluorinated compounds under high temperatures and pressures, or some halogen units. There is no problem with the absorption of fluids (such as water) by polytetrafluoroethylene. The working temperature of polytetrafluoroethylene is -150 ° C to 180 ° C.

(4) Ethylene propylene diene monomer (EPDM) rubber. EPDM rubber originates from the copolymerization of ethylene and propylene, and is recommended for use with hydraulic fluids based on phosphate esters, brake fluids based on ethylene glycol, hot water, and water vapor above 150 ° C. It can also be used with polar solvents and has the characteristics of oxygen resistance, ozone resistance, and light resistance. The working temperature of EPDM rubber is -40 ° C to 130 ° C.

(5) Silicone rubber (Q-MQ-MVQ). Silicone rubber includes a variety of rubber materials, and is composed of methyl acetate and vinyl rubber. It is suitable for engines, transmission oils, animal or vegetable fats, but is not recommended to be used together with water vapor, silicon fat, fuel and aromatic hydrocarbons. It has the characteristics of weather resistance, ozone resistance and aging resistance, and is physiologically neutral, with good high and low temperature resistance. The working temperature of silicone rubber is -50 ° C to 190 ° C.

3. Hard sealing materials and their applications

Generally, globe valves, gate valves, check valves, regulating valves, etc. are equipped with hard seals. If excellent sealing performance is required, soft seals will be chosen accordingly.

(1) Copper alloy. Copper alloy has good corrosion resistance and wear resistance in water or steam, and is suitable for media with PN ≤ 1.6MPa and temperature not exceeding 200 degrees. It can be fixed on the body by ring structure or welding and melting casting methods. The commonly used grades are ZCuAl10Fe3 (aluminum bronze) and ZCuZn38Mn2Pb2 (cast brass).

(2) Chromium stainless steel. Chromium stainless steel has good corrosion resistance and is commonly used in media such as water, steam, oil, and temperatures not exceeding 450 degrees Celsius. The commonly used grades are 2Cr13 and 1Cr13.

(3) Sitaili alloy. Corrosion resistance of Si Tai Li hard alloy. It has excellent comprehensive properties such as erosion resistance and abrasion resistance, and is suitable for various valves and media with temperatures ranging from -268 to+650 degrees Celsius, especially for highly corrosive media. It is one of the ideal sealing surface materials. (Recommended by valve manufacturer: China Guowei Valve Manufacturing Co., Ltd.) Due to its high price, Sitaili alloy is often welded.

(4) Nickel based alloys. Nickel based alloys are another important type of material in the field of corrosion resistance. There are three commonly used sealing surface materials: Monel, Hastelloy B, and Hastelloy C. Monel is the main material resistant to hydrofluoric acid corrosion, suitable for alkaline, salt, and food environments with temperatures ranging from -240 to+482 degrees Celsius, and acid solvent media without air. Hastelloy B and Hastelloy C are the most corrosion-resistant materials for valve sealing surfaces, suitable for corrosive mineral acids, sulfuric acid, phosphoric acid, wet HCI gas, and strong oxidizing media at a temperature of 371 degrees Celsius (hardness 14RC); Meanwhile, it is suitable for chlorine free solutions and strongly oxidizing media with a temperature of 538 degrees Celsius (23RC).

(5) Iron based alloys. Iron based alloys are a newly developed sealing surface material in China, with better wear resistance and abrasion resistance than 2Cr13, as well as certain corrosion resistance, which can replace 2Cr13. Suitable for non corrosive media with temperature less than or equal to 450 degrees. Common grades include WF311 and WF312 iron-based powders.

Applet

Scan code for more attention

Official account

Scan code for more attention

TikTok

Scan code for more attention

Alibaba

Scan code for more attention

Scan code for more attention